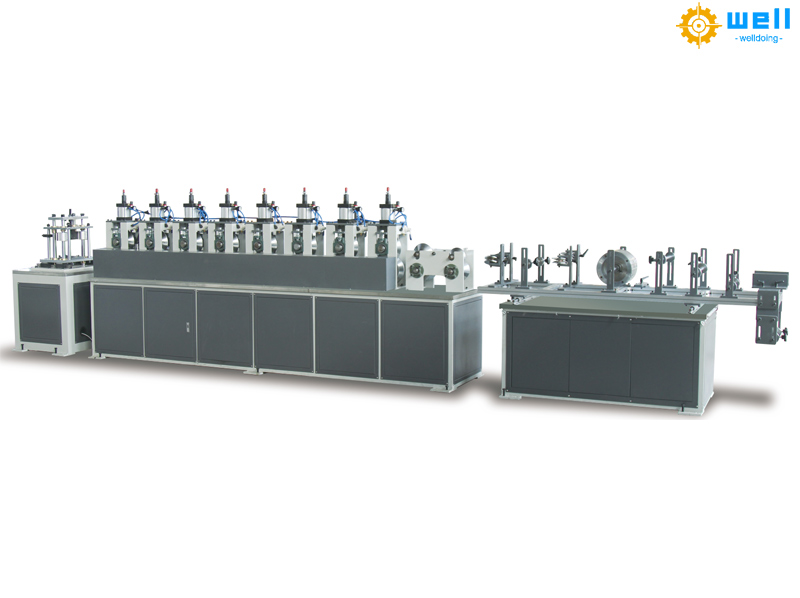

The parameter adjustment of the fully automatic Automatic paper edge protector machine is mainly achieved through its control system (PLC and touch screen), which involves key aspects such as process parameters, operating speed, and pressure control.

Process parameter setting

By using the touch screen human-machine interface (HMI) to input process parameters for each workstation (such as spray gun fan-shaped atomization parameters, glue volume, etc.), the parameters will be saved to the touch screen variables and synchronized to the internal variables of the PLC through communication lines. Before the spraying begins, the PLC outputs the process parameters as analog quantities to control the opening of the proportional valve of the spray gun to adjust the process effect.

Operating speed and pressure control

Speed regulation: The Paper edge protector making machine speed can be adjusted through a touch screen or speed control device, typically ranging from 0-35 meters per minute. For example, the ZJD-100A production line supports speed control to adapt to different production needs.

Pressure adjustment: The pneumatic pressure regulating device is used to accurately control the pressing position and force of the forming wheel, with a pressure adjustment range of generally 0.1-0.6 MPa. By adjusting the air pressure, the tightness and consistency of the corner guard molding can be changed.

Cutting and functional configuration

Cutting parameters: The minimum cutting length can be set (such as 100mm), and the cutting accuracy can reach ± 1mm. Hydraulic cutting, servo tracking cutting, or flying cutting system can be selected, and the specific method needs to be adjusted according to the specifications and material thickness of the corner guard.

Function extension: Optional printing device can be equipped, and the mold can be automatically converted through a cylinder to achieve multi machine production of L-shaped, U-shaped, and flat corner protectors.

Safety and maintenance tips for paper corner protector production line

Fault handling: If the process parameters are set improperly and cause a fault, it is recommended to maintain the fault phenomenon through the touch screen and trigger an audible and visual alarm until the operator resets.

Signal filtering: If the analog control signal has a large error, time filtering or average filtering should be used to optimize data stability.

Example of Operation Process

Pre startup check: Confirm that the device is in its initial state (green indicator light).

Parameter input: Set parameters such as speed and pressure on the touch screen interface, save them, and synchronize them to the PLC.

Operation monitoring: Real time display of operation status, speed, and sorting data through touch screen, supporting parameter reset and mode switching.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975

Post time: Nov-04-2025