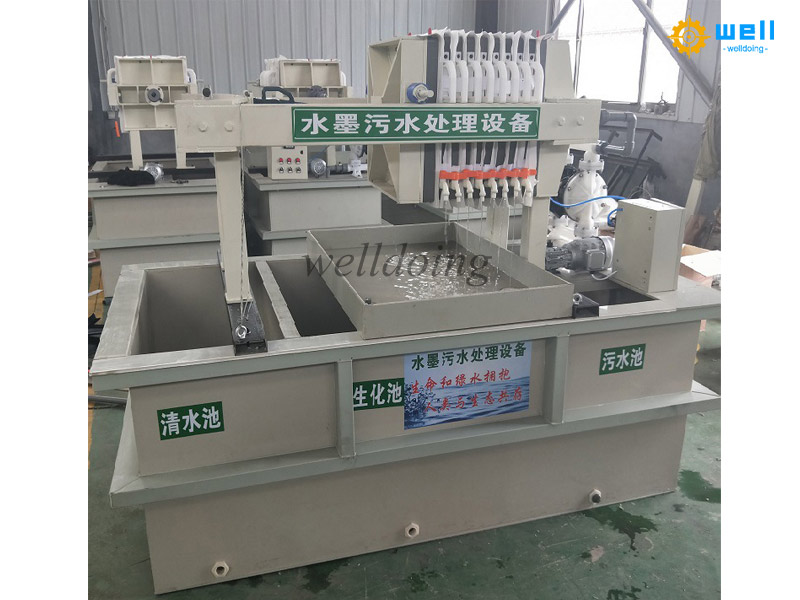

ink waste water treatment machine is mainly used to treat various types of wastewater generated in the production process of the printing industry. Its core functions and application scenarios are as follows:

1、 Main processing objects

Ink wastewater: contains organic compounds such as pigments, resins, solvents, etc., with COD concentration reaching thousands of mg/L and extremely high chromaticity.

Runplate liquid wastewater: wastewater containing surfactants, isopropanol, and other pollutants generated during the offset printing process.

ink printing sewage treatment machine cleaning wastewater: wastewater containing ink particles generated during the cleaning of printing press cylinders, plates, etc.

Developer/plate making wastewater: Waste liquid containing photosensitizers and resins generated during the CTP plate making process.

2、 Core processing function for flexo ink printing wastewater treatment machine

Removing chromaticity: By using techniques such as air flotation and adsorption, the turbidity of the effluent is reduced to less than 10mg/L.

Degradation of organic matter: Reduce COD/BOD to emission standards (such as GB4287-2012).

Solid liquid separation: Removing suspended solids (such as ink particles, paper fibers).

Heavy metal removal: for special printing wastewater containing lead and chromium ions.

3、 Typical application scenarios

Printing factory: deals with wastewater from processes such as offset printing, gravure printing, and flexographic printing.

Packaging factory: deals with printing wastewater such as cardboard boxes and plastic packaging.

Plate making center: deals with CTP plate making machine and resin plate developing wastewater.

Ink production workshop: deals with ink blending and container cleaning wastewater.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975

Post time: Sep-26-2025