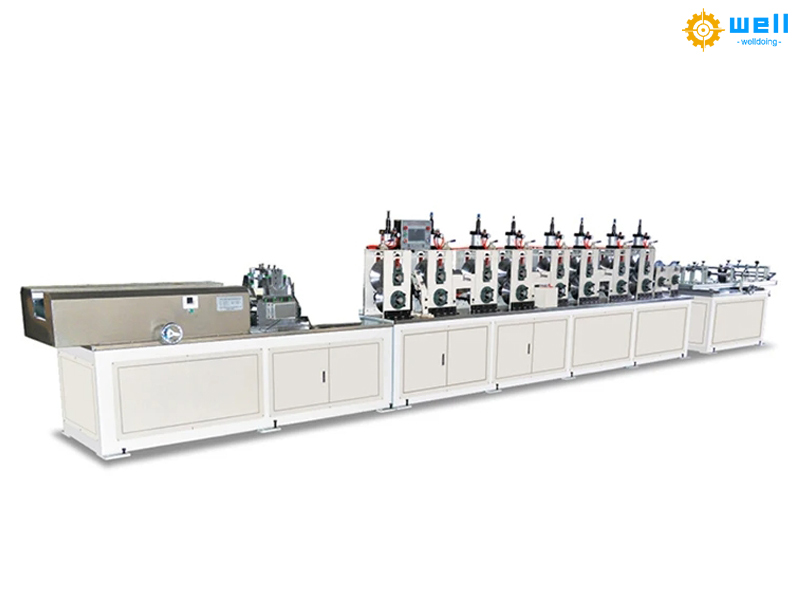

The paper corner board making machine is a specialized equipment used for manufacturing paper corner protectors (also known as paper wrapped corners or corner protectors). Its technical principle is mainly based on paper lamination molding and automated processing technology.

1、 Structure and function of paper corner protectors

Paper corner protectors are usually made by bonding and pressing multiple layers of kraft paper or recycled paper with glue, with a cross-sectional shape of “L” or “U”, mainly used for:

Packaging reinforcement (such as corner protection of cardboard boxes)

Shelf support (to prevent deformation during product transportation)

Replacing wooden/plastic corner protectors is environmentally friendly and cost-effective.

2、 The core technical principle of Paper edge protector making machine

1. Raw material preparation and feeding system

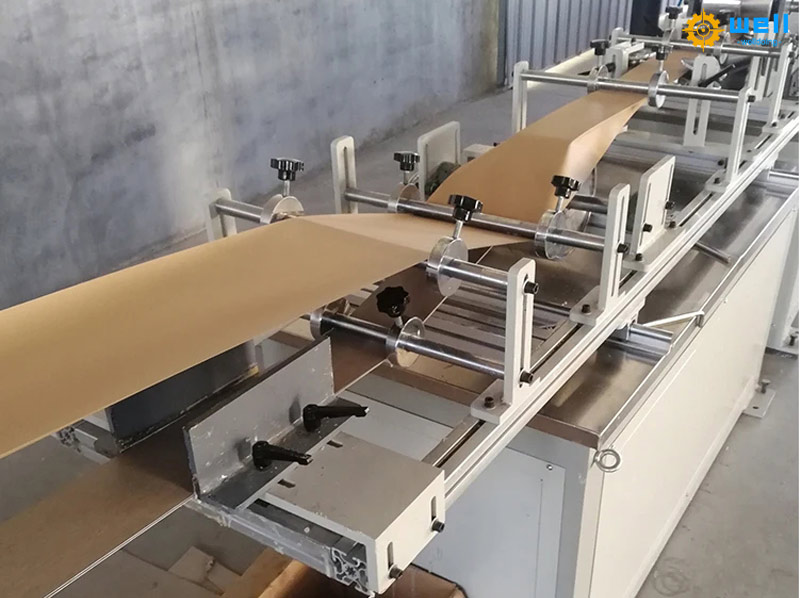

Roll paper unwinding: Multi layer kraft paper (usually 2-5 layers) is unwinding at a constant speed through a tension control device.

Adhesive coating: Apply adhesive (such as PVA adhesive or hot melt adhesive) evenly between paper layers using roller coating or spray coating.

Preheating treatment (optional): Infrared or hot air heating softens the paper to improve adhesive strength.

2. Laminated molding

Multi layer composite: The paper is laminated layer by layer by multiple pressure rollers to form a thick paper strip.

Right angle forming: The flat paper tape is pressed into a 90 ° angle using an “L” mold (or bending mechanism), and the core equipment includes:

Pre bending unit: progressive bending to avoid paper breakage.

Forming roller: High pressure roller (pressure up to 5-10 tons) ensures sharp edges.

3. Drying and curing

Hot air drying: 80-120 ℃ hot air circulation accelerates the curing of glue.

Cold pressing shaping: The cooling roller group eliminates thermal deformation and stabilizes dimensions.

4. Cutting and cutting

Vertical slitting: The circular knife slitting machine cuts into strips according to the width requirements.

Fixed length cutting: servo controlled flying knife or sawing device (accuracy ± 1mm).

5. Automated auxiliary system

PLC control: Coordinate the speed, temperature, and pressure parameters of each unit.

Correction device: The photoelectric sensor adjusts the paper deviation in real time.

Waste edge recycling: automatic winding or crushing of scraps.

3、paper angle board making machine Production process flow:

Roll paper unwinding → gluing/preheating → multi-layer composite → L-shaped bending forming → hot pressing shaping → cooling → slitting/cutting → finished product stacking

4、 Technical difficulties and solutions

Interlayer adhesive opening

Reason: Uneven glue or insufficient pressure.

Solution: Increase the penetration process of glue (such as ultrasonic assisted glue coating) and raise the pressing temperature.

Edge burrs

Reason: Tool wear or mismatched cutting speed.

Solution: Using diamond coated blades to optimize cutting angles.

Energy consumption control

Optimization: Infrared drying replaces traditional hot air and waste heat recovery system.

5、 Industry Development Trends

High speed: The production line speed has been increased from 20m/min to 50m/min (requiring high-precision servo control).

Green manufacturing: water-based adhesives, solvent-free composite technology.

Intelligence: AI visual detection of corner protection defects, remote operation and maintenance of the Internet of Things.

If you need further information on specific models or process debugging, we can provide your production requirements (such as corner protector thickness, production capacity, etc.) and contact us as soon as possible.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975

Post time: Jun-09-2025