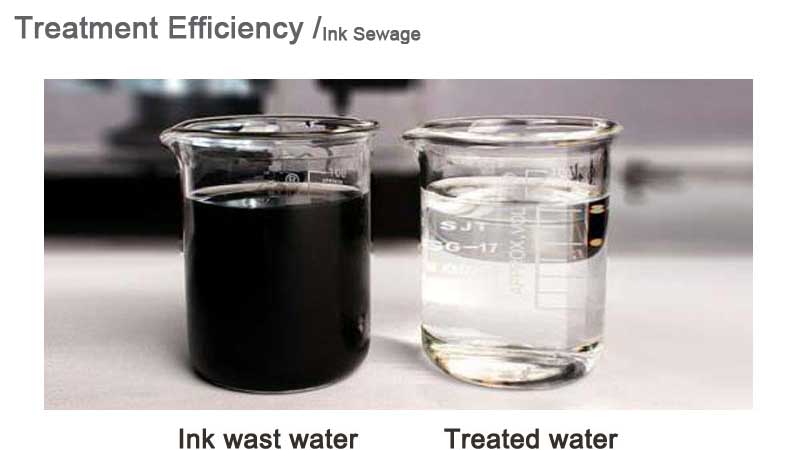

The use of ink waste water treatment machine involves various processes and operating standards.

1、 Core processing technology ink sewage treatment equipment

Coagulation air flotation: By adding coagulants (such as polyaluminum chloride) and coagulants (such as polyacrylamide), ink particles are condensed and combined with tiny bubbles to float and separate, suitable for the removal of colloidal pollutants.

Electrolysis method: using iron/aluminum electrodes to produce redox reactions, decompose organic matter, and improve the biodegradability of wastewater, often used as a pretreatment method.

MBR membrane technology: Combining biodegradation and membrane separation, the effluent quality is high and the sludge volume is small, suitable for reuse scenarios.

2、 Equipment operation process

Power on preparation: Check the power supply, pipeline connections, and medication inventory to confirm that the ink printing sewage treatment machine is normal.

Operation control:

Automatic mode: Automatically start and stop pumps, fans, and other equipment based on the water level in the regulating pool.

Manual mode: The aeration tank fan, lift pump, and MBR self-priming pump (applicable to the sludge cultivation stage) need to be started in sequence.

Shutdown maintenance: Close the inlet valve and motor, clean the filter membrane, discharge sludge, and record operating parameters.

3、 Precautions

Safety protection: Wear protective equipment during operation to avoid contact with electrical components.

Water quality monitoring: Regularly monitor pH value (6-9), COD, and suspended solids concentration to prevent damage to biofilm.

Maintenance points:

The oil of the fan should be changed every 6 months, and the air inlet should be kept unobstructed.

MBR membrane needs to be backwashed regularly to prevent blockage.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975

Post time: Sep-30-2025