To determine whether waste water treatment clear machine needs maintenance, a comprehensive evaluation of multidimensional indicators is required, combined with real-time monitoring and regular inspections. The following are the key criteria and methods for judgment:

1、 Abnormal operating status

Changes in effluent quality

If the effluent is turbid, the color is abnormal, or the detection indicators (COD/BOD/SS) exceed the standard, it is necessary to check the aeration uniformity of the biological reaction tank, the sludge status of the sedimentation tank, and the operation of the disinfection device.

Regularly calibrate water quality monitoring instruments (such as level sensors and flow meters) to ensure data accuracy.

Equipment performance degradation

When the flow rate of pump equipment decreases by more than 20%, it is necessary to check for valve blockage or pipeline leakage.

Fan noise, abnormal temperature, or loose V-belt may indicate mechanical failure.

2、 Mechanical and electrical system inspection

Lubrication and Sealing

Check the oil level and quality of the fan oil tank, and replace it promptly if it deteriorates; Clean the air filter to prevent blockage.

Leakage of sealing components or wear of impellers in pump equipment should be dealt with immediately.

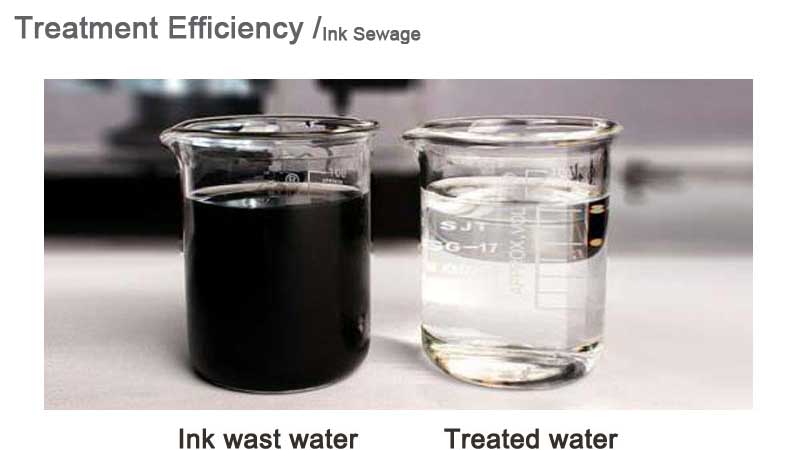

Electrical component status ink waste water treatment machine

Overheating or loose wiring of contactors and relays inside the control cabinet may cause malfunctions and require regular tightening and cleaning.

3、 Intelligent monitoring and early warning

Real time collection of device parameters (such as oil temperature, pressure, current) through remote monitoring system, triggering multi-channel alarms in case of abnormalities.

Utilize CCTV technology to detect internal corrosion or blockage of aeration heads in pipelines and intervene in advance.

4、 Seasonal maintenance requirements

In winter, it is necessary to strengthen insulation measures (such as laying insulation boards) to prevent low temperatures from affecting the activity of bacterial strains in the biochemical tank.

5、 Maintenance priority suggestion

Emergency maintenance: Any malfunctions that directly affect operation, such as excessive water discharge or equipment shutdown, must be dealt with immediately.

Planned maintenance: Clean the grille and lubricate the transmission components periodically to avoid cumulative wear.

By dynamically evaluating the above indicators, maintenance needs can be accurately identified and combined with intelligent means to improve the domestic sewage treatment equipment operation and maintenance efficiency.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975

Post time: Oct-24-2025