Core advantages of Greyboard production line

1、 Progressiveness process

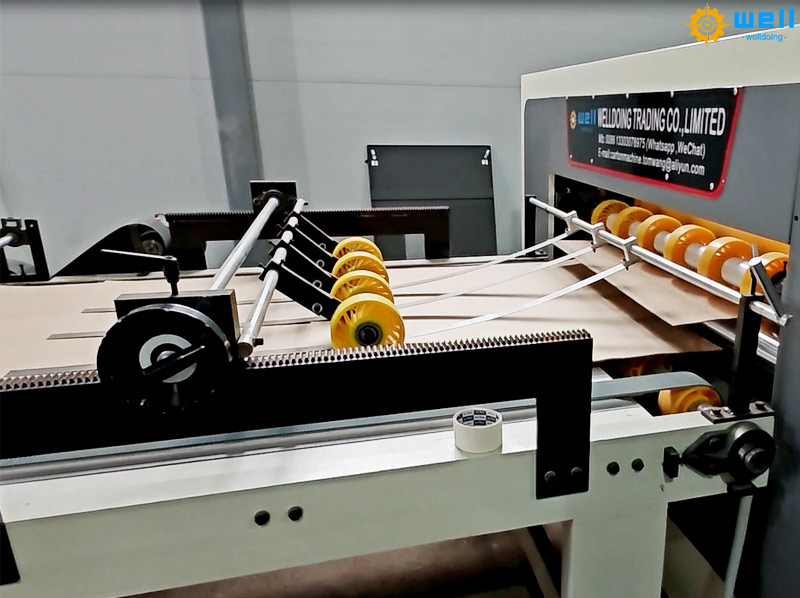

Long network machine interconnection composite technology

Advanced equipment in Europe adopts a long wire machine connected composite process to achieve synchronous molding of the core board and surface paper, ensuring uniform and high flatness of the gray board structure.

Some domestic production lines still use the method of pre producing core paper and then laminating it, which requires multiple gluing and drying processes and may affect stability.

Multi layer composite capability

Support three-layer to seven layer composite (such as single gray, double gray, full gray board) to meet different strength requirements.

The six layer composite production line can process industrial grade cardboard, suitable for high demand scenarios such as color box packaging.

2、 Equipment configuration and efficiency

High speed production

The Paper solid composite production line speed can reach 100-300 meters per minute, with a daily output of up to 100000 cardboard boxes (seven layer line).

Equipped with automated equipment such as hydraulic paper racks and steam preheaters to reduce manual intervention.

Customized design

The width covers 1200-3000mm and supports customization needs for small and medium-sized cardboard box factories (such as single-sided units).

Some devices are integrated with a quick change system for cartridges, which shortens the time for changing orders.

3、 Quality and environmental advantages Cardboard composite production line

Raw material and structural control

European FSC regulates waste paper raw materials to ensure transparent grey boards with better fiber properties; Some domestic manufacturers improve their quality by importing waste paper.

Patent technology, such as Fujian Lishu’s multi-layer composite grey board paper, can enhance wear resistance and aesthetics.

Environmental compliance

The recycled paper process conforms to the low-carbon trend, and some equipment is compatible with the domestic waste paper classification system.

4、 Application scenario extension

Widely used in high-end fields such as luxury packaging and electronic product packaging, balancing stiffness and printing adaptability.

Industrial grade production lines can process special purpose materials such as cushioning pads and display boards.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975

Post time: Sep-26-2025