The paper corner protector machine is used to produce paper corner protectors. Paper corner protector (also known as corner protector or edge protector) is a green packaging material widely used to protect product edges and enhance packaging strength. Its production equipment has clear types.

Core types of equipment (classified by product type and process)

Paper corner protectors are mainly divided into “equilateral right angle type” and “irregular shape (such as rounded corner, U-shaped, bent type)”, corresponding to different production lines.

1. Equilateral right paper corner board making machine

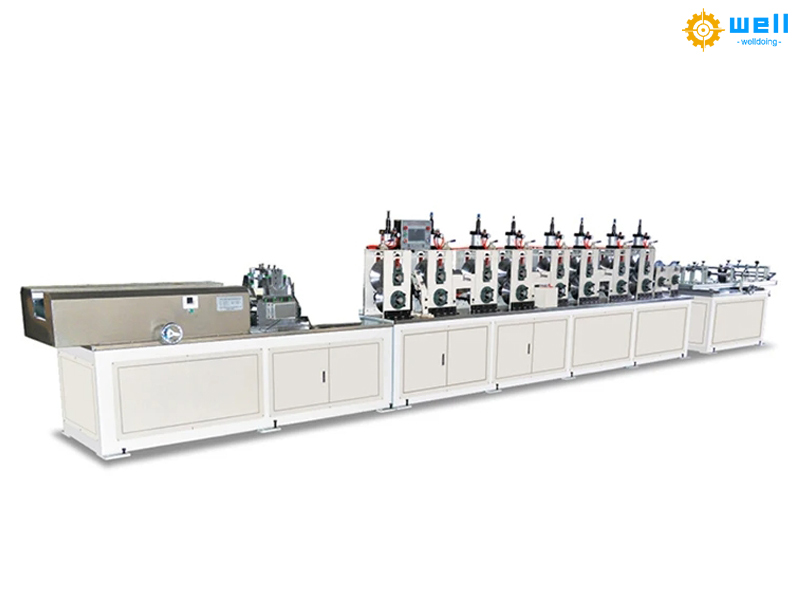

This is the most common and basic type used for producing long strip corner protectors.

Production process: Roll paper → Multi layer adhesive composite → Drying and shaping → Longitudinal cutting and slitting → Fixed length cutting → Material receiving/packaging.

Features of the equipment:

Continuous production: From raw paper to finished products, it can be automated continuously with high efficiency.

The core lies in lamination and forming: through multiple sets of rolling units, multiple layers of kraft paper are firmly adhered and pressed into a tight 90 degree right angle structure.

Adjustable speed and specifications: By changing molds and adjusting parameters, products with different edge lengths (such as 30x30mm, 40x40mm, 50x50mm, etc.), thicknesses, and lengths can be produced.

2. Production paper angle board making machine for irregular paper corner protectors

Used for producing products that are not right angled or require secondary processing.

Rounded/arc-shaped corner protection production line: On the basis of the right angle production line, special arc-shaped forming molds are added to make the product cross-section arc-shaped, which is used to protect cylindrical items.

U-shaped corner protector production line: capable of forming U-shaped cross-section corner protectors at once, used to wrap and protect two adjacent faces and one edge of an object.

Bending/chamfering machine (post-processing equipment): This is a very important auxiliary equipment. It uses straight strip products produced from the right angle corner protector production line as raw materials for:

Fixed length cutting.

Bending at specific angles (such as 90 degrees, 135 degrees, etc.) is used to make corner protectors and wrapping parts for tray corners.

Cut/groove: facilitates the installation and fitting of corner protectors at the corners of the box.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975

Post time: Jan-23-2026