The grey board production line is a complete set of equipment specifically used for producing gray cardboard (also known as gray bottom white board paper, gray board paper), and its products are widely used in packaging, printing, stationery, handicrafts and other fields. The following is a detailed introduction to the Paper hardboard production line :

1、 Introduction to grey cardboard

Grey cardboard is usually composed of multiple layers of structure, with a white or colored coating on the surface and gray waste paper pulp on the bottom layer. Common types include:

Single layer gray cardboard: a single layer of gray cardboard.

Double gray board: both sides are gray, and the middle layer is made of waste paper pulp.

All grey board: made entirely from recycled paper, without coating.

White gray board: The surface is coated with a white coating, and the bottom layer is gray.

2、 Main equipment of automatic grey board prodution line

Pulp making system

Pulper: crushes waste paper (such as old newspapers, cardboard boxes) into pulp.

Screening and purification equipment: remove impurities (plastics, metals, etc.).

Beating machine: Adjust fiber length to improve paper strength.

Paper machine (core equipment)

Slurry box: evenly distribute pulp to the forming net.

Forming section (long net/round net): Multi layer paper sheet forming (grey cardboard usually requires multi-layer composite).

Pressing section: Dehydration is achieved through mechanical pressure.

Drying section: Steam dryer for drying paper sheets.

Surface sizing/coating (optional): Improve surface smoothness and printability.

Pressing and coiling

Polishing machine: Improve the flatness and glossiness of paper.

Paper rolling machine: Roll paper into large rolls.

Cutting and packaging

Roll slitting machine: Cut into small rolls or flat sheets according to customer needs.

Packaging machine: Automated packaging of finished products.

3、 Production process flow

Raw material preparation: waste paper classification → shredding → de ink (if white layer is required).

Slurry preparation: Mix different slurries (bleached pulp for the surface layer and waste pulp for the bottom layer).

Multi layer molding: forming a multi-layer structure through the composite of multiple networks.

Dehydration and drying: Pressing and dehydrating → drying → controlling moisture content (about 8-10%).

Post processing: coating (optional) → calendering → slitting → inspection (thickness, stiffness, smoothness).

4、 Key Technologies and Characteristics

Multi layer composite technology: ensuring the thickness and stiffness of the grey cardboard.

Energy saving design: such as reducing energy consumption through heat recovery systems.

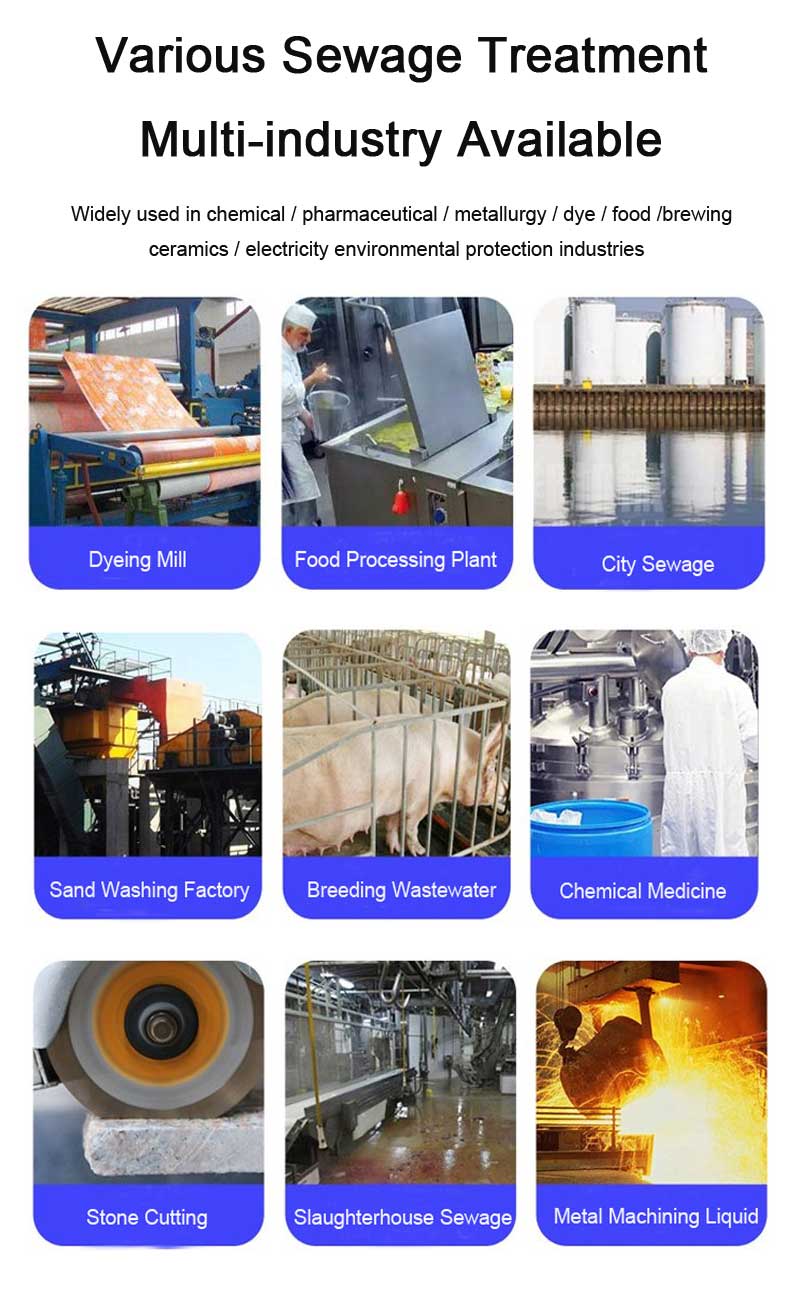

Environmental requirements: wastewater treatment (recycling), exhaust gas treatment (boiler flue gas).

Automation control: PLC/DCS system adjusts parameters such as temperature, speed, tension, etc.

5、 Application Fields

Packaging industry: gift boxes, shoe boxes, electronic product liners.

Printing industry: book covers, postcards.

Industrial use: gaskets, partitions.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975

Post time: Jun-17-2025