The installation of the fully Automatic box stitching machine must strictly follow technical specifications to ensure stable operation and optimal performance of the equipment. The specific installation requirements are as follows:

1. Site preparation

Ground flatness: The installation location should be on a concrete hardened ground with a horizontal error of ≤ 2mm/m ² to avoid displacement caused by equipment vibration.

Space requirement: Reserve an operating space of 3m in front of and 1.5m on both sides of the Automatic double piece jiont stitching machine for maintenance and material turnover.

Environmental conditions: recommended temperature of 10-40 ℃, humidity ≤ 80%, keep away from dust and corrosive gases.

2. Basic installation

Equipment fixation: Tighten the ground embedded parts with anchor bolts (M16 or above), and the bolt torque should reach 120N · m.

Gas source connection: The compressed air pressure should be stable at 0.6-0.8MPa, equipped with an oil-water separator, and the gas pipe interface should be G1/4.

Power configuration: three-phase 380V ± 10% power supply, power ≥ 15kW, grounding resistance ≤ 4 Ω.

Paper feeding calibration: Adjust the gap between the octagonal wheels to a cardboard thickness of+0.2mm, and set the vacuum adsorption pressure to -0.05MPa.

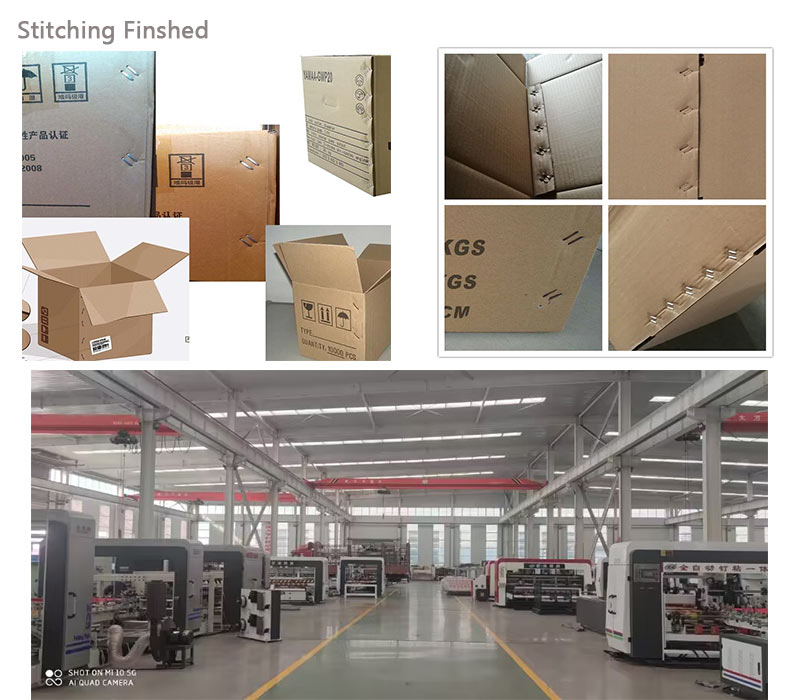

Nail distance setting: Input parameters through the PLC touch screen (adjustable from 30-70mm), and the first piece needs to undergo nail strength testing (≥ 800N).

Safety protection: Install photoelectric sensors to ensure that the operating area is unobstructed before the equipment can be started.

4. Online compatibility

If it is necessary to connect with the automatic cardboard stitching machine and packaging machine, the conveyor belt speed (error ± 5%) and stacking height (≤ 1.2m) need to be adjusted synchronously.

Precautions

After installation, run the bearing without load for 30 minutes to check for temperature rise (≤ 45 ℃) and abnormal noise.

Before the first use, special lubricating grease should be applied to vulnerable parts such as nail heads and crimping wheels.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975

Post time: Sep-28-2025