Welcome to our websites!

News

-

Energy saving of flexo ink printing slotting die cutting machine

Methods for achieving energy-saving in automatic printer die cutter slotter machine 1、 Optimize equipment structure The structure of printing equipment has a significant impact on energy efficiency, so optimizing the equipment structure to achieve energy conservation is an effective method. For ...Read more -

Preparation work and operation process of partition assembly machine

The cardboard Partition assembly machine is a device used for producing cardboard grids, and its operation process is usually as follows: 1、 Preparation work a. Equipment inspection: Before operating the cardboard slot machine, a comprehensive inspection of the equipment is required to ensure th...Read more -

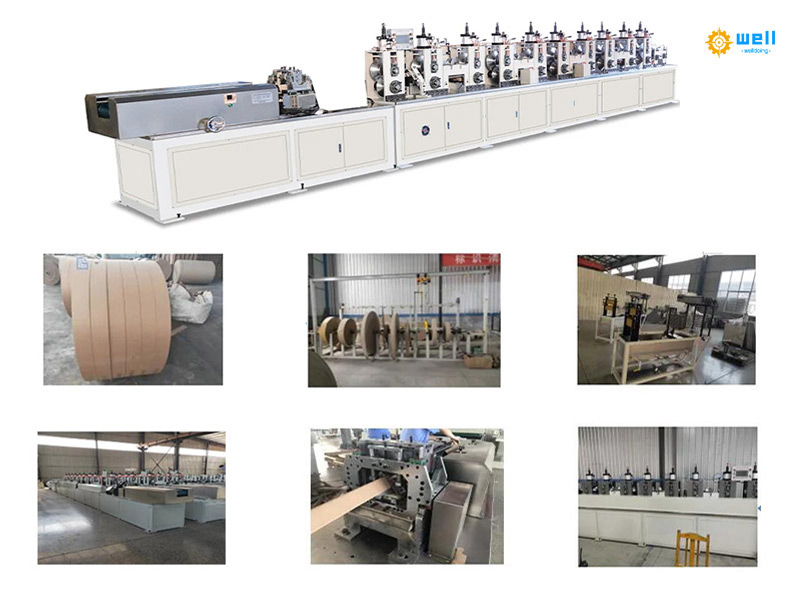

Inspection work of paper tube making machine

Before application, the condition of each component of the automatic paper tube making machine should be carefully checked, such as the condition of electrical equipment, switches, insulation of electrical circuits, whether screws and nuts are fixed, and whether the protector is safe. After addin...Read more -

Installation of the paper hardboard production line

The installation of the automatic hardboard production line must strictly follow technical specifications to ensure equipment accuracy and production safety. The following are the key steps and precautions: 1、 Preparation before installation Venue and Foundation Confirm the basic load-bearing ca...Read more -

Main functional features of paper corner protector machine

paper corner board making machine is a professional equipment used for producing paper corner protectors. Its main functional features include efficient automation production, flexible adaptation to different specifications, and the production of paper corner protectors with excellent protective ...Read more -

The maintenance of sewage treatment equipment

The maintenance of ink sewage treatment equipment should take targeted measures based on the equipment type, environmental characteristics, and operating status. 1、 Core equipment maintenance Blower fan Regularly clean the intake filter to prevent impurities from damaging the impeller; Check the...Read more -

Safety operating for automatic partition inserter machine

What are the safety operating procedures for Automatic partition assembly inserter machines? 1. The slot machine must be operated by professionally trained personnel according to the operating procedures. 2. Ensure that the mechanical moving parts of the grid insertion machine are well lubricated...Read more -

The working principle and application scope of paper tube equipment

paper tube making machine plays an important role in industrial production. Below, we will introduce its working principle and application scope. The working principle of CNC paper tube core making machine varies by type, but overall there are similarities. Taking the common paper tube machine as...Read more -

Ensure operation of high-speed cardboard printing machine

Ensure the normal operation of the Automatic carton printing die cutting slotting machine 1、 Check before startup Equipment status check: Confirm that the cutting tools and screws are not loose, the paper feeding table is free of debris, and the lubrication system oil level is sufficient. Safety...Read more -

Cleaning method for dirt on grey cardboard production line

Cleaning method for dirt on Greyboard production line Optimization of raw material ratio When using 100% waste book and newspaper pulp, it is necessary to strengthen the screening of raw materials to avoid impurities (such as tape and plastic) from entering the production line and reduce equipmen...Read more -

How to calibrate the dimensions of paper corner protector machine?

Dimensional calibration method for paper corner board making machine Equipment installation inspection Use a spirit level to ensure that the machine is installed horizontally, fix all screws, and avoid dimensional deviations caused by looseness. Roller alignment and pressure adjustment Check the ...Read more -

How does paper tube equipment meet energy-saving requirements?

With the development of the economy, the consumption of resources is also constantly increasing. In order to meet the goals of sustainable development, it is currently required to achieve energy conservation as much as possible in the process of production operations. This requires not only impro...Read more