Welcome to our websites!

News

-

Fully automatic cardboard partition assembly machine

The precautions for using the fully automatic Partition assembly machine mainly include the following aspects: Basic cleaning and lubrication After use, dust, paper scraps, and other debris on the surface of the machine should be cleaned in a timely manner to keep the equipment clean and prevent ...Read more -

The treatment process of sewage treatment machine

The treatment process of ink sewage treatment equipment 1. Preprocessing Purpose: To carry out preliminary treatment of sewage, remove large suspended particles, oil and other impurities, and provide good conditions for subsequent treatment. Common methods: grid filtration, sedimentation tank, re...Read more -

Technical requirement for use of composite cardboard production line

Technical requirements for the use of composite automatic hardboard production line: 1. When using the initial strip, the tension should be adjusted to the appropriate position, that is, whether it is loose or not. 2. When the strip shrinks, adjust the tensioner in a timely manner to relax the te...Read more -

Adaptation of paper tube machine in packaging industry

In the packaging industry, the application scenarios of paper tubes are diverse, from food packaging to industrial parts packaging, with significant differences in demand. automatic paper tube making machine needs to be adjusted accordingly to meet the requirements of different packaging for pape...Read more -

Fully automatic carton box folding gluing machine

The preventive maintenance of the Automatic carton box folding gluing machine is the key to ensuring stable operation and extending the service life of the equipment. The following are specific maintenance methods: Cleaning and maintenance After daily work, the power should be turned off and the ...Read more -

Automatic paper corner protecting machine

paper angle edge corner protector machine are mainly used for producing L-shaped and U-shaped paper corner protectors. Paper corner protectors are applied in the construction industry, aluminum industry, steel industry, and other metal industries to prevent damage to product edges and corners dur...Read more -

Safety preparation for paper board partition assembler machine

First, Safety preparation for paperboard partition assembler machine 1. Before the high-speed partition assembler machine equipment enters the site, it is necessary to check whether the appearance certificate, mechanical operation certificate and other relevant documents of the equipment are comp...Read more -

Optimizing the printing quality of cardboard box printing machine

Optimizing the printing quality of Flexo printer die cutter slotter machines requires precise adjustment from multiple stages such as paper feeding unit, printing unit, slotting and die-cutting unit. Paper feeding unit adjustment The core of the paper feeding unit is to ensure that the cardboard ...Read more -

Angle adjustment of the paper tube making machine

The angle adjustment of the automatic paper tube making machine is an important part of ensuring the quality of the paper tube, and its core lies in adjusting the entry angle of the slitting raw paper and the horizontal state of the equipment. Angle adjustment steps Equipment startup and prelimin...Read more -

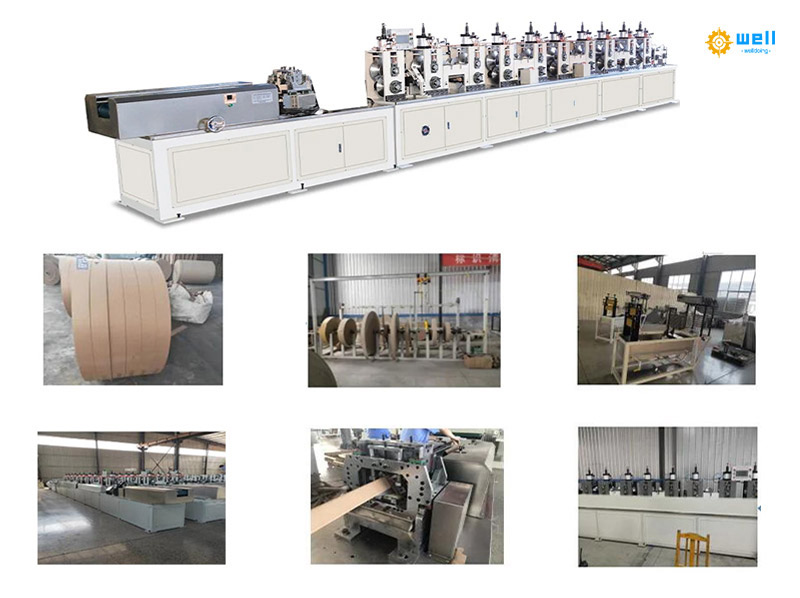

Improve the production of grey hardboard production line

Improving the production capacity of automatic hardboard production lines requires multiple aspects such as equipment upgrades, process optimization, and intelligent transformation. 1、 Equipment performance optimization By upgrading core equipment such as palletizing robots, the packing speed ca...Read more -

Semi-automatic carton box stitching machine

In the modern packaging industry, Semi-automatic box stitiching machines have gradually become the preferred equipment for carton packaging due to their high efficiency, stability, and ease of operation. Working principle of semi-automatic carton box stitching machine The Semi automatic carton st...Read more -

Adjust the parameters of automatic paper edge protector machine

The parameter adjustment of the fully automatic Automatic paper edge protector machine is mainly achieved through its control system (PLC and touch screen), which involves key aspects such as process parameters, operating speed, and pressure control. Process parameter setting By using the touch s...Read more