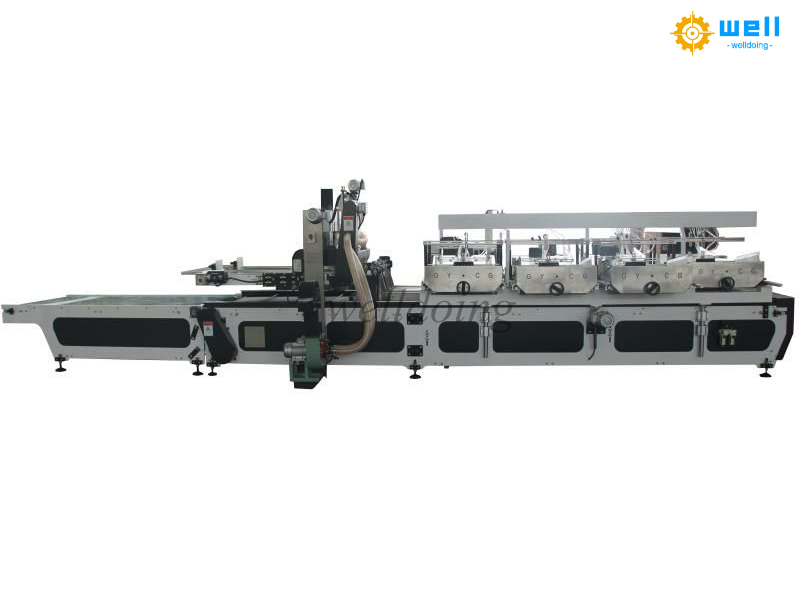

The cardboard Partition assembly machine is a device used for producing cardboard grids, and its operation process is usually as follows:

1、 Preparation work

a. Equipment inspection: Before operating the cardboard slot machine, a comprehensive inspection of the equipment is required to ensure that it is in normal working condition. This includes checking the integrity of various components of the equipment, such as conveyor belts, grid cutters, motors, etc., as well as checking the lubrication and safety devices of the equipment for normal operation.

b. Prepare raw materials: Prepare the required cardboard raw materials according to production needs. Ensure that the quality of the cardboard meets the requirements and the dimensions are accurate. At the same time, it is necessary to prepare corresponding tools and auxiliary materials, such as glue, tape, etc.

c. Parameter setting: According to production requirements, set the relevant parameters of the Automatic partition assembly inserter machine, such as grid size, grid depth, grid spacing, etc. The setting of these parameters will directly affect the quality and specifications of the cardboard inserts produced, so careful adjustment and confirmation are required.

2、 Operation process

a. Loading: Place the prepared cardboard raw materials on the feeding platform of the cardboard inserting machine, ensuring that the cardboard is oriented correctly and can smoothly enter the conveyor belt.

b. Conveyor belt transportation: Start the conveyor belt to transport the cardboard raw materials to the grid area. The speed of the conveyor belt should be adjusted according to production needs to ensure that the cardboard can be smoothly transported to the grid position.

c. Grid insertion operation: When the cardboard is transported to the grid insertion area, the grid insertion knife will automatically insert into the cardboard and insert according to the preset parameters. During the grid insertion process, it is important to observe the quality and effectiveness of the grid insertion, such as whether it is neat and whether the depth meets the requirements. If any problems are found, the grid parameters should be adjusted or repaired in a timely manner.

d. Discharge: After the grid is inserted, the paper cardboard automatic partition assembly machine will transport the inserted cardboard to the discharge platform. The operator needs to promptly remove the cardboard from the discharge platform, organize and stack it.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975

Post time: Dec-05-2025