Textile printing and dyeing Sewage treatment machine is a system specifically designed to treat industrial wastewater generated in the printing industry. Its core goal is to remove pollutants such as ink, solvents, heavy metals, and organic matter from the wastewater, ensuring compliance with discharge standards or achieving reuse.

The main components and characteristics of printing water

Typical pollutants:

Ink particles (including pigments, resins, and solvents)

Heavy metal ions (such as lead, chromium, mercury, from certain inks)

Organic solvents (ethanol, ethyl acetate, toluene, etc.)

High COD (Chemical Oxygen Demand) and BOD (Biochemical Oxygen Demand) values

High chromaticity (wastewater often appears dark)

Wastewater source:

Printing machine cleaning wastewater

Printing plate washing wastewater

Runban liquid wastewater

Waste ink and solvents

The core process and equipment of ink printing sewage treatment machine

Printing wastewater treatment usually adopts a combination of physical, chemical, and biological processes, and the specific equipment is selected according to water quality and discharge standards:

1. Preprocessing stage

Grille/sieve machine

Remove large suspended particles such as paper scraps and plastic sheets.

Regulating pool

Balance water quality and quantity, equipped with pH adjustment system (acid/alkali neutralization).

2. Physical and chemical treatment

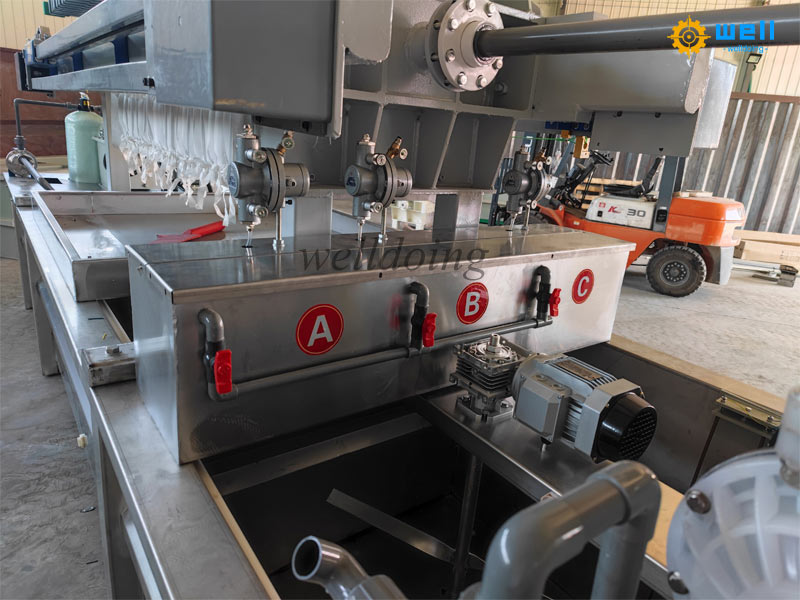

Coagulation sedimentation system

Equipment: coagulation reaction tank, flocculation tank, inclined plate sedimentation tank

Chemicals: PAC (polyaluminum chloride), PAM (polyacrylamide)

Function: Remove colloidal particles, some COD, and chromaticity.

Air flotation machine of the flexo ink printing wastewater treatment machine (DAF or dissolved air flotation)

Applicable: Ink and grease containing wastewater, separated by microbubble adsorption and flotation.

Activated carbon adsorption tower

Application: Deep removal of dissolved organic matter and chromaticity.

3. Advanced oxidation treatment

Ozone oxidation equipment or Fenton reactor

Applicable: Difficult to degrade organic compounds (such as resins and solvents), which decompose pollutants through strong oxidation.

UV photocatalytic oxidation

Combining ozone or hydrogen peroxide (H ₂ O ₂) to improve degradation efficiency.

4. Biological treatment

MBR membrane bioreactor

Combining microbial degradation and membrane filtration, the effluent quality is high and can be reused.

biological contact oxidation tank

Suitable for wastewater with good biodegradability (BOD/COD>0.3).

5. Deep processing and reuse

Ultrafiltration (UF)+reverse osmosis (RO) system

Realize wastewater desalination and reuse, suitable for high demand scenarios.

Ion exchange resin tower

Remove heavy metal ions such as lead and chromium.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975

Post time: May-30-2025