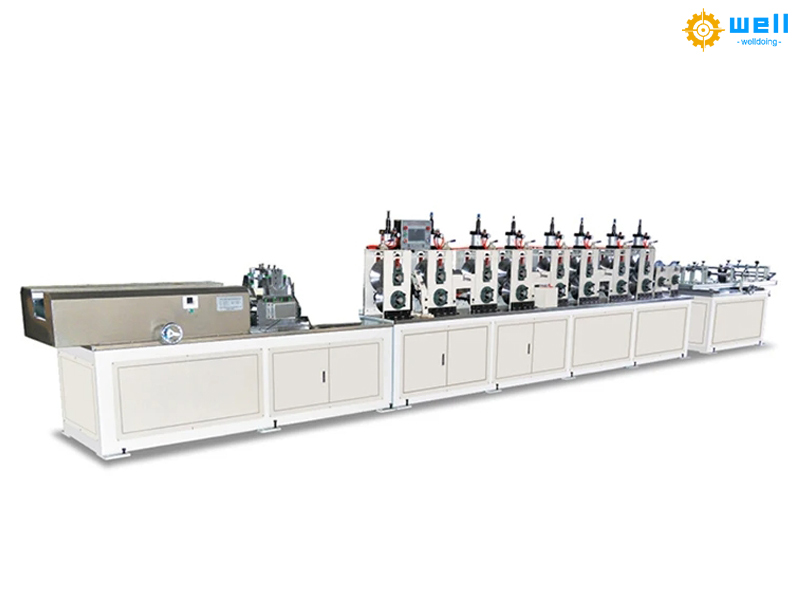

As a key equipment in the production of Automatic paper edge protector machine, the technical characteristics of paper corner protectors mainly include automation, precision control, process adaptation, and environmental friendliness

1. Automation and efficient production

Adopting a fully automated design process, integrating functions such as feeding, positioning, and belt fixation, the placement time of single box corner protectors can be shortened to 10-20 seconds, with efficiency increased by more than 5 times compared to manual labor.

Support linkage with winding machines and tape machines to form an automated production line, for example, in home appliance packaging, the integrated operation of “corner protection tape application winding” can be achieved.

2. High precision positioning technology

By using photoelectric sensors and servo motors, a positioning accuracy of ± 1mm is achieved, and the deviation of the corner guard fitting does not exceed 2mm, avoiding random errors caused by manual operation.

Some models adopt an electronic cam “dual flying shear” control system to ensure the synchronization and stability of the cutting and pressing processes.

3. Multi specification adaptability

The feeding channel for corner protectors and the conveyor track for cardboard boxes can be electrically adjusted, supporting the production of corner protectors with a width of 30-100mm and a thickness of 2.5-8mm. Switching specifications only takes 3-5 minutes.

Compatible with various corner protection structures such as L-shaped, U-shaped, and C-shaped, and capable of stamping special shapes or printing logos to meet diverse packaging needs.

4. Energy saving and environmental protection processes

The drying technology using electric heating wire or air source heat pump heating optimizes energy consumption while improving the strength and durability of paper corner protector production line.

The paper corner protectors produced by the equipment can be 100% recycled, in line with the low-carbon packaging concept, replacing traditional wooden or plastic corner protectors.

5. Intelligent control

Some high-end models integrate tension control systems, which adjust material tension in real time through PLC programming to ensure the dimensional accuracy and compressive performance of paper corner protectors during the production process.

The intelligent monitoring system can optimize parameters such as drying temperature and polishing force to improve the yield of finished products.

6. Economy and durability

The equipment investment cost ranges from 68000 to 500000 yuan, supporting small batch customization and reducing the initial investment pressure for enterprises.

Adopting a high-strength mechanical structure design, it adapts to continuous production needs and has low maintenance costs.

In summary, the technological core of paper corner protector machine lies in achieving efficient, environmentally friendly, and flexible production through automation, precision control, and intelligent processes, meeting the dual requirements of cost and quality in the modern packaging industry.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975

Post time: Oct-09-2025