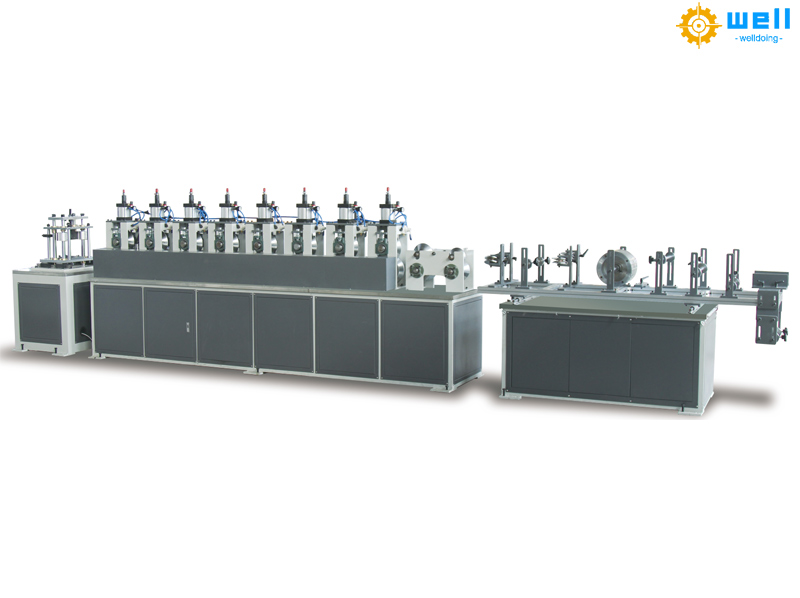

The Automatic paper edge protector machine equipment is a specialized machinery used for manufacturing paper corner protectors, a type of packaging protection material. Its core functions include paper guiding, gluing, forming, cutting, and stacking, enabling the production of L-shaped, U-shaped, or flat-plate corner protectors to meet different packaging needs.

Equipment type and core functions:Multi-functional production line can switch between producing L-shaped, U-shaped, or flat paper corner protectors, achieved through pneumatically operated lifting molds, without the need to replace the entire machine.

Integrated automatic gluing, hydraulic cutting, and servo control, with an accuracy of ±1mm, supporting specifications with side lengths ranging from 25-120mm and thicknesses from 2.5-8mm.

Auxiliary equipment: Drying equipment: Microwave dryer for drying paper corner protectors, with a processing speed of 30m/min.

Bending equipment: PLC-controlled, capable of switching between convex and concave molds for processing shaped corner protectors.

The performance characteristics of paper angle edge corner protector machines mainly include the following aspects:

1. Production specifications and speed specifications range: The side length of the produced paper corner protector is usually between 25mm and 125mm, and the thickness is between 2mm and 10mm. Some equipment can be adjusted to produce corner protectors with unequal sides.

Production speed: The speed range is wide, varying from 0-15m/min to 0-70m/min, depending on the equipment model and configuration.

2. Automation and Operational Convenience: The degree of automation is achieved through the use of PLC computer programming technology, frequency control, and a human-machine interface input control system, ensuring ease of operation.

Operational convenience: Some equipment supports automatic clutching, automatic synchronization, and automatic tensioning devices, reducing manual intervention.

3. Quality and Stability: Quality Control: Utilizing a unique air pressure system, the tightness of the corner protection surface can be freely adjusted, ensuring that the product is sturdy and the edging is smooth and aesthetically pleasing.

Stability: Some equipment utilizes high-density, large-diameter molding pressure wheels, allowing for arbitrary specification adjustments without the need to change pressure wheels.

4. Versatility and Applicability Versatility: Some paper angle board making machine can produce corner protectors and paper flat plates separately, as well as punch and crease corner protectors, adapting to various packaging needs.

Applicability: Widely used in logistics, transportation packaging, and other fields, meeting the packaging needs of different industries.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975

Post time: Jan-04-2026