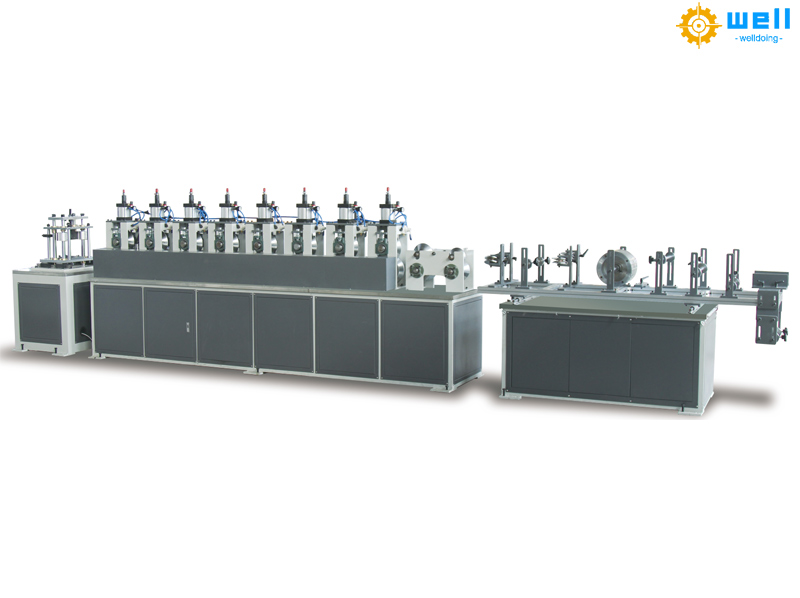

Usage and operation specifications of paper angle edge corner protector machine

1. Equipment type and function

Corner protectors are mainly divided into two categories: horizontal corner protectors and vertical corner protectors:

Horizontal corner protector: Used in conjunction with a downward pressure belt punching machine to achieve synchronous operation of corner protector and belt punching.

Vertical corner protector: capable of simultaneously placing four corner protectors, suitable for high-speed ring winding machines or pallet online winding machines.

2.automatic paper edge protector machine Preparation before operation

Check the equipment status:

Confirm that the power and gas supply pipelines are not damaged and the grounding is reliable.

Check if the suction cup structure is intact (latent design can reduce wear).

Materials and Tools:

Select corner protection specifications according to requirements (such as 40 × 4mm right angle anti-collision corner protection).

Prepare measuring tools (vernier caliper, angle ruler).

3. Operation steps

Horizontal corner protector

Start the device: Run it without load for 1-2 minutes and observe the smoothness of operation.

Place corner protectors:

Place the corner protector into the storage bin and adjust the suction cup strength (with an error controlled within 5-15mm).

By using photoelectric sensing devices for positioning, ensure that the protective corners are aligned with the edges of the cardboard box.

Linkage strapping: Cooperate with the downward pressure strapping machine to complete the fixation of corner protectors.

Vertical corner protector

Multi station placement:

Utilize eight storage bins and place corner protectors on all four sides simultaneously (increasing efficiency by over 50%).

Wrapping fixation:

Linked with the high-speed ring winding machine, the corner protector is automatically wrapped and fixed with film after placement.

4. Safety precautions

Protective equipment: Wear protective gloves and goggles during operation to avoid injury from splashing corner protectors.

Emergency handling: If the equipment is abnormal (such as suction cup failure), immediately stop the paper corner protector machine and check the pneumatic components.

Prohibited behavior:

Do not remove safety devices (such as photoelectric sensors).

Do not adjust the corner guard position while the device is running.

5. Maintenance and upkeep

Daily cleaning: Remove paper scraps and oil stains from suction cups and guide rails.

Lubrication and maintenance: Add lubricating oil to moving parts such as bearings and chains every week.

Regular inspection: Monthly testing of photoelectric sensing accuracy and calibration errors.

By standardizing operation and maintenance, the positioning accuracy of the corner protector can be improved (error ≤ 5mm) and the equipment life can be extended.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Email:cartonmachine.tomwang@aliyun.com

Phone/Wechat/Whatsapp:+86 13303078975

Post time: Sep-28-2025