- Full automatic die cutting machine

- Ink Waste Water Treatment Machine

- paper angle board machine

- carton folder gluer machine

- hard paper board production line

- Carton stitching machine

- Paper tube making machine

- corrugated carton Printer slotter die cutter machine

- Slotting machine

- stacking machine

- thin blade machine

- partition assembler machine

-

automatic carton partition assembler

Certification : ISO9001 ,CE

Application : Commodity, Machinery & Hardware, Textile, Alcohol, Toy, Chemical, Apparel, Gifts & Arts, Dining, Medical, Food

After- Sales Service Provided: Overseas Third-Party Support Available

Automatic Grade: Automatic

Adapt to the object: yogurt, fresh milk, fruit juice drinks

Adapt to the industry: catering, food, gifts, crafts

After-sales service: the warranty period is for all one year

Product size: 7300 * 2000 * 2000 (mm)

-

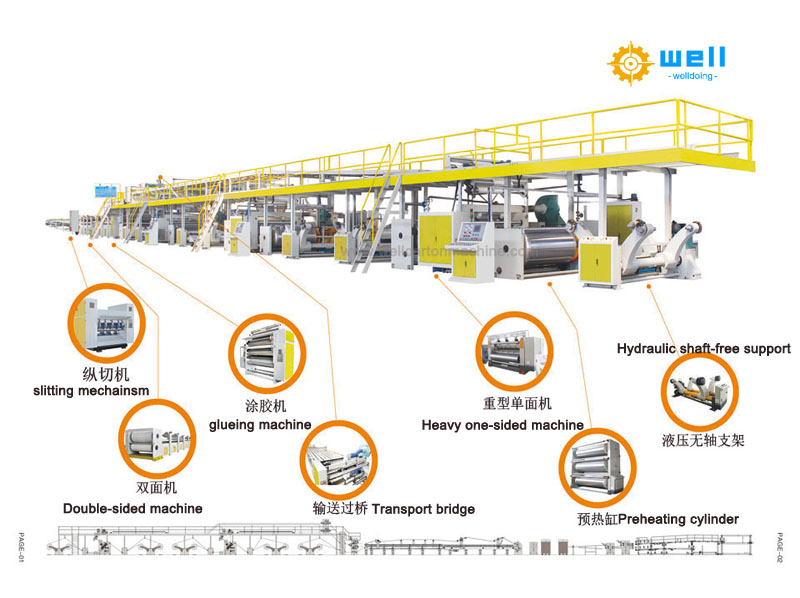

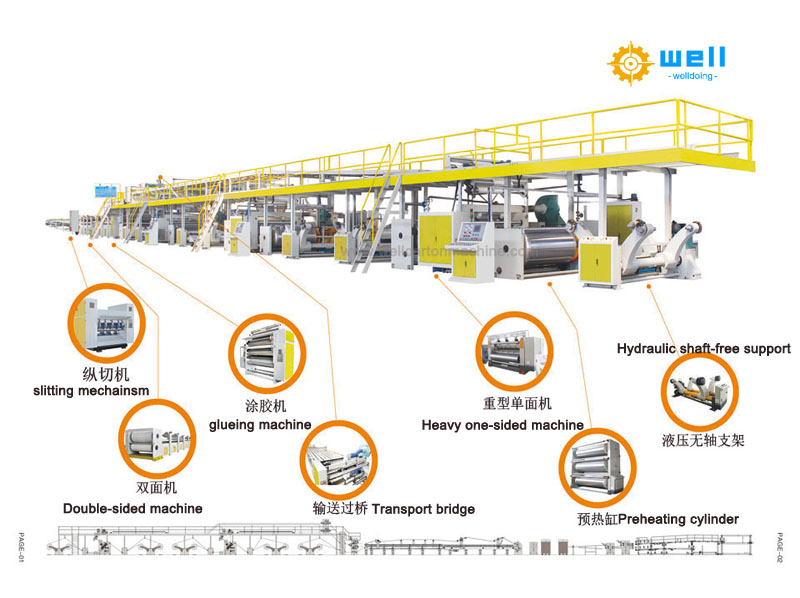

Hardboard production line grey board making machine

Corrugated cardboard hardboard production line has complete models. Please consult customer service for detailed customization parameters Three (five) layer corrugated board production line Five layer corrugated cardboard production line is composed of suction corrugated machine, hydraulic base paper rack, automatic paper receiving machine, gluing machine, dryer, straight knife paper cutter, single (double) layer preheating cylinder and corner plate receiving platform, with a mechani... -

Full automatic corrugated cardboard partition assembly machine

- Application:Chemical, Machinery & Hardware, Medical, Textiles

- Packaging Type:Cartons, Film

- Packaging Material:Paper, Wood

- Automatic Grade:Automatic

- Driven Type:Electric, Electric

- Voltage:220V/380V

-

3,5,7 ply corrugated cardboard hardboard production line

corrugated board production line has complete models. Please consult customer service for detailed customization parameters Corrugated cardboard hardboard production line 3,5,7ply corrguated cardboard production line is composed of suction corrugated machine, hydraulic base paper rack, automatic paper receiving machine, gluing machine, dryer, straight knife paper cutter, single (double) layer preheating cylinder and corner plate receiving platform, with a mechanical speed of 1... -

automatic juice and milk carton partition assembly machine

- Application:Chemical, Machinery & Hardware, Medical, Textiles

- Packaging Type:Cartons, Film

- Packaging Material:Paper, Wood

- Automatic Grade:Automatic

- Driven Type:Electric, Electric

- Voltage:220V/380V

-

EPE Foam Pipe Making Machine

Product name: EPE Foam Pipe Making Machine

Characteristics of finished Product

–High resilience and buoyant effect.

–Effective insulating capability.

–Low thermal conductivity.

–Negligent absorption and water permeability.

–Chemical resistant.

–Effective and safe to handle in installation application.

–Non-toxic and environmental friendly

–Fine round closed-cell cellular structure assure

–Excellent flexibility.

-100% recyclable and reusable. -

Automatic corrugated box partition assembly insert machine

- Application:Chemical, Machinery & Hardware, Medical, Textiles

- Packaging Type:Cartons, Film

- Packaging Material:Paper, Wood

- Automatic Grade:Automatic

- Driven Type:Electric, Electric

- Voltage:220V/380V

-

EPE Foam Tube Making Machine

Product name: EPE Foam Tube Making Machine

Characteristics of finished Product

–High resilience and buoyant effect.

–Effective insulating capability.

–Low thermal conductivity.

–Negligent absorption and water permeability.

–Chemical resistant.

–Effective and safe to handle in installation application.

–Non-toxic and environmental friendly

–Fine round closed-cell cellular structure assure

–Excellent flexibility.

-100% recyclable and reusable. -

autoamtic juice carton partition assembler machine

- Application:Chemical, Machinery & Hardware, Medical, Textiles

- Packaging Type:Cartons, Film

- Packaging Material:Paper, Wood

- Automatic Grade:Automatic

- Driven Type:Electric, Electric

- Voltage:220V/380V

-

EPE Foam Rod Making Machine

Product name: EPE Foam Rod Making Machine

Characteristics of finished Product

–High resilience and buoyant effect.

–Effective insulating capability.

–Low thermal conductivity.

–Negligent absorption and water permeability.

–Chemical resistant.

–Effective and safe to handle in installation application.

–Non-toxic and environmental friendly

–Fine round closed-cell cellular structure assure

–Excellent flexibility.

-100% recyclable and reusable. -

Beer carton furit box corrugated cardboard partition assembly equipment

- Application:Chemical, Machinery & Hardware, Medical, Textiles

- Packaging Type:Cartons, Film

- Packaging Material:Paper, Wood

- Automatic Grade:Automatic

- Driven Type:Electric, Electric

- Voltage:220V/380V

-

carton box partition assembler equipment

- Application:Chemical, Machinery & Hardware, Medical, Textiles

- Packaging Type:Cartons, Film

- Packaging Material:Paper, Wood

- Automatic Grade:Automatic

- Driven Type:Electric, Electric

- Voltage:220V/380V