- Full automatic die cutting machine

- Ink Waste Water Treatment Machine

- paper angle board machine

- carton folder gluer machine

- hard paper board production line

- Carton stitching machine

- Paper tube making machine

- corrugated carton Printer slotter die cutter machine

- Slotting machine

- stacking machine

- thin blade machine

- partition assembler machine

-

automatic die cutting and creasing machine

1. adopting the central positioning system

2. The high-speed precision leading edge paper feeding device

3. Variable frequency control and air volume regulation

4. The patented servo motor control

5. PLC control, safer and more reliable.

-

automatic cardboard carton die cutting machine

1. adopting the central positioning system

2. The high-speed precision leading edge paper feeding device

3. Variable frequency control and air volume regulation

4. The patented servo motor control

5. PLC control, safer and more reliable.

-

automatic paper feeding die cutting machine with waste cleaning

1. adopting an independent motion control unit

2. having automatic movement state

3. Be suitable for many different types of paper.

4. Wall Panel Material: nodular cast iron

Upper and lower platform: nodular cast iron

Five castings: integrated casting

-

Double piece semi-automatic nailing stitcher machine

mechanical speed: 600 nailing/min.

stitching distance :30-130mm is adjustable

working table lifting effective height :900mm

Our company with high standards of quality requirements, with product specialization, advanced automation, enterprise scale become the benchmark of nail box machine industry, products sold all over the country in domestic and foreign markets.

-

semi automatic double pieces carton stitching machine

mechanical speed: 600 nailing/min.

stitching distance :30-130mm is adjustable

working table lifting effective height :900mm

Our company with high standards of quality requirements, with product specialization, advanced automation, enterprise scale become the benchmark of nail box machine industry, products sold all over the country in domestic and foreign markets.

-

manual servo model double head box stitching machine

Semi-automatic stitching machine main part and function introduction : 1. Schneider france original import four servo motor drive ,high precise with few mechnical driving part ,reduce the machine damage 2 box stitching machine wenlun touch screen ooperation the parameter ( nail distance, nail unmber,nail types,tial gate ) change convinently 3 The box stitching machine control system use the omron plc control system 4..back electrical baffle use the stepper motor driven ,size accurat... -

manual double servo stitching machine

Semi-automatic stitching machine main part and function introduction : 1. Schneider france original import four servo motor drive ,high precise with few mechnical driving part ,reduce the machine damage 2 box stitching machine wenlun touch screen ooperation the parameter ( nail distance, nail unmber,nail types,tial gate ) change convinently 3 The box stitching machine control system use the omron plc control system 4..back electrical baffle use the stepper motor driven ,size accurat... -

Semi-automatic box stitching machine

Processing custom: yes

outline dimension: 2900mm*2000mm*1920mm

Mechanical weight:1650kg

Use horsepower:6hp

Applicable cardboard:3 Layer, 5

Mechanical width:2800mm

pitch of nails:30mm~120mm

Paper counting method:Automatic counting

mechanical system:servo

Control mode:touch screen

-

corrugated carton box stitching machine

Semi-automatic stitching machine main part and function introduction : 1. Schneider france original import four servo motor drive ,high precise with few mechnical driving part ,reduce the machine damage 2 box stitching machine wenlun touch screen ooperation the parameter ( nail distance, nail unmber,nail types,tial gate ) change convinently 3 The box stitching machine control system use the omron plc control system 4..back electrical baffle use the stepper motor driven ,size accurat... -

Automatic carton box folder gluer machine – supplier & manufacturer

Product alias: fully automatic nail packing machine

Finished product size: 16000 * 3500 * 1800

Packaging type: box

Applicable to: milk tea, yogurt, fresh milk, fruit juice drinks, carbonated drinks, smoke, other

Applicable industries: catering, food, toys, tobacco and alcohol, medicine

-

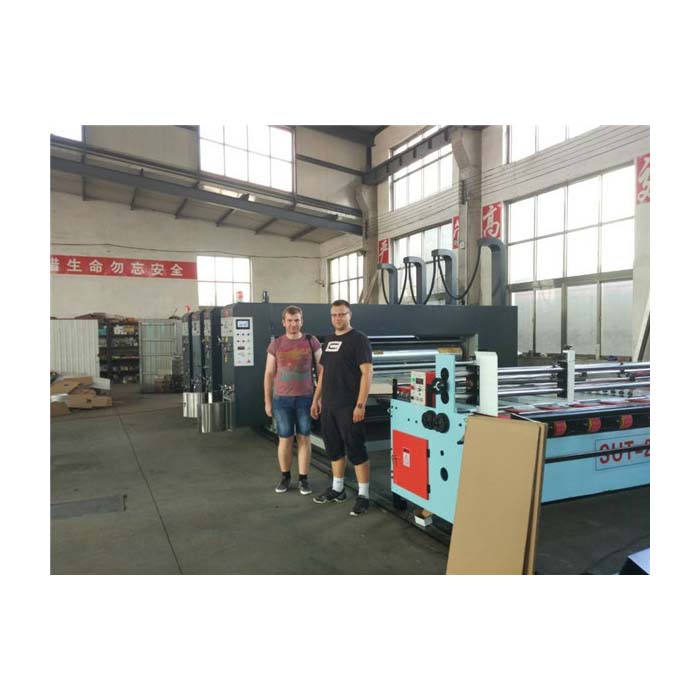

Semi automatic chain feeding printer slotter rotary die cutter

1. The main functions and uses of the carton printing slotting machine Carton printing and slotting machine This machine can complete the functions of printing, slotting, edge separation and crimping of corrugated cardboard at one time. It has the advantages of exquisite printing, high precision and fast efficiency. The adjustment range of each adjustment mechanism is large, and it can be adapted to three, five and seven layers of cardboard. Technical parameters of CN102-1425 two-color printi... -

Breeding wastewater treatment machine

Processing customization: Yes

Treatment amount of sewage: 0.5-100 (m3/h) m_ / h

Product name: Ink and wash sewage treatment equipment

Air volume: 40 (m3/min)

Exit pipe diameter: 20 (mm)